|

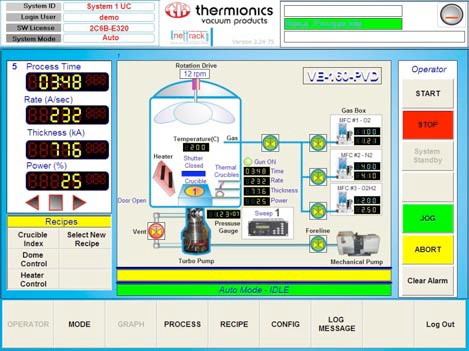

| VE-160 PVD Coating System |

|

This thin film tool has a wide range of uses, including solar, optical, battery, fuel cell, semiconductor, and nanotechnology applications. It is ideal for laboratories, university instruction, research & development, prototyping, and production. With a small footprint, it is compatible with cleanroom operation and maintenance.

Features

■ Multiple sources all available in the same chamber:

• e-Gun electron beam evaporation • Sputtering • Resistive deposition

■ Sources and utilities mounted on a single flange for simple swap and maintenance.

■ Source-to-substrate distance up to 24”, ideal for high-uniformity and liftoff processes.

■ PC Control System

■ Less than 15 minutes from atmosphere to process pressure of 10e-6 Torr.

■ Modular, expandable design with choice of “standard options.”

■ Easy access through 20” X 19” door to large 16” X 16” X 35” work space.

|

| Specifications |

| Deposition sources |

• 3 kW, 6 kW, and/or 10 kW e-Gun evaporation sources

• DC and RF sputtering sources up to 10kW available

• 1kVA and 2kVA dual resistive evaporation sources available |

| Source Mounting |

e-Gun and sputtering sources and utilities are mounted on a single flange for quick change or replacement. Resistive evaporation sources can be mounted on either of two levels of ports provided. |

| Chamber work space |

16” X 16” X 35” |

| Substrate flange |

ISO quick access |

| Vacuum process chamber |

304 stainless steel, “D” style chamber with hinged front door. |

| Cycle time |

Less than 15 minutes from atmosphere to process pressure of 10e-6 Torr |

| Ports |

Spare ports for installation of all standard options |

| Electrical |

220 VAC 3-phase or 400 VAC 3-phase |

| Water |

1.5 gpm to 3 gpm, depending on source selection. Water flow is factory interlocked for proper flow rate. |

| Air |

60 psi air supply |

| Finish |

Cleanroom compatible paint finish |

| Dimensions |

Overall dimensions 24”L X 44”W X 68.5”H (61cm L X 112 cm W X 174 cm H) |

|

|

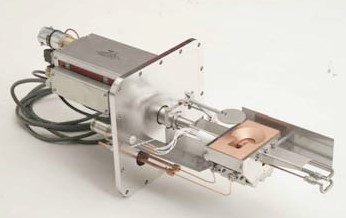

| VE-90 Resistive Vacuum Coating System |

|

The VE-90 is an economical system ideally suited to resistive coating applications. Its straightforward controls and rapid cycle time enhance productivity. Reliable coating chores are accomplished in a high vacuum environment that is available in about ten minutes from atmosphere with the touch of a single button.

| Specifications |

| Evaporation System |

• 1 kVA resistive evaporation source

• 2 switch-selectable pairs of baseplate feedthroughs

• Digital ammeter readout |

| Pressure Instrumentation |

• Digital ionization gauge

• Digital Convectron gauge |

| Vacuum System |

• 12” x 12” Pyrex bell jar

• Dual-stage mechanical pump

• Turbomolecular pump

• Automatic pumpdown with source interlocks |

| Utilities |

115/220 VAC at 20 A |

| Physical Specifications |

• Tubular steel frame with casters and side panels

• 30” L x 20” W x 42” H

• Approx. 250 lbs. |

| Options |

• 2 kVA resistive evaporation package

• Substrate fixture

• Substrate shutter

• Thickness monitor |

|

|

|