|

Atomic Layer Deposition System

|

|

Chemical Vapor Deposition System

|

ALD (Atomic layer deposition ) has a number of advantages such as excellent uniformity, film conformality with identical film thicknesses deposited on the wafer surface even complex shapes substrates, low temperature processing.

Therefore, ALD is applied for many applications in the field of microelectronics, nanotechnology and biotechnology which often working on soft substrates, such as organic and biological samples. Therefore, ALD is applied for many applications in the field of microelectronics, nanotechnology and biotechnology which often working on soft substrates, such as organic and biological samples. |

|

CVD (Chemical Vapor Deposition) is a process in which the substrate is exposed to one or more volatile precursors, reacting and decomposing on the substrate surface to create the desired thin film deposit.

This method is often used to fabricate high quality, high performance, solid material in vacuum environment. Therefore, this process commonly used in the semiconductor industry to fabricate thin films. This method is often used to fabricate high quality, high performance, solid material in vacuum environment. Therefore, this process commonly used in the semiconductor industry to fabricate thin films. |

|

Microwave Annealing System

|

|

Benchtop Freeze Dryer

|

MWA (Microwave Annealing) is a next generation leading edge heating technology, which will be required for sub 20nm chip manufacturing. Low temperature annealing of thin films on silicon wafers, used in the fabrication of semiconductor devices is both selective and volumetric, throughout the material, as compared with external heating via thermal transfer in IR heaters (e.g. RTP). Low temperature annealing of thin films on silicon wafers, used in the fabrication of semiconductor devices is both selective and volumetric, throughout the material, as compared with external heating via thermal transfer in IR heaters (e.g. RTP). |

|

A freeze dryer removes water from a perishable material in order to preserve it, extending its shelf life and/or making it more convenient for transport.

Freeze dryers work by freezing the material, then reducing the pressure and adding heat to allow the frozen water in the material to change directly to a vapor (sublimate). Freeze dryers work by freezing the material, then reducing the pressure and adding heat to allow the frozen water in the material to change directly to a vapor (sublimate). |

|

Digital Mass Flow Meters and Controllers

|

|

Industrial Thermal Mass Flow Meters

|

Sierra's Premium Digital, Economical / OEM and Traditional Analog mass flow meters and controllers can measure mass flow rate of any clean dry gas including mixtures, toxics and corrosives. The scientific product line utilizes "Capillary Tube Thermal" sensing technology and are widely used for precise measurement of very low flows (i.e. 0-10 sccm) as well as higher full scale flow ranges up to 1000 slpm (full scale up to 5600 slpm available upon request). flow rate of any clean dry gas including mixtures, toxics and corrosives. The scientific product line utilizes "Capillary Tube Thermal" sensing technology and are widely used for precise measurement of very low flows (i.e. 0-10 sccm) as well as higher full scale flow ranges up to 1000 slpm (full scale up to 5600 slpm available upon request). |

|

Sierra's Industrial thermal products utilize “Immersible Thermal” sensing technology and are widely used for precise mass flow measurement in light-industry, heavy-industry, hazardous environments, and Ultra High Purity (UHP) applications. Rugged and reliable, Sierra's industrial thermal mass flow meters are work horses in industry and are commonly used to measure Air and Natural Gas as well as all other industrial gases and mixtures. mass flow measurement in light-industry, heavy-industry, hazardous environments, and Ultra High Purity (UHP) applications. Rugged and reliable, Sierra's industrial thermal mass flow meters are work horses in industry and are commonly used to measure Air and Natural Gas as well as all other industrial gases and mixtures. |

|

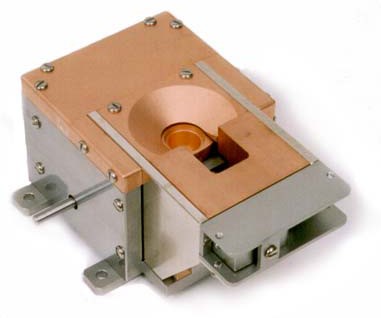

e-Guns

|

|

Ion Pumps

|

Thermionics e-Gun, an electron beam evaporation source, is used to produce uniform high-purity films and optical coatings. The compact design and ease of maintenance make it useful in practically all vacuum systems and for many varied applications. It has been used to evaporate refractory and dielectric materials, as well as the more common conductive and semiconductor materials. e-Gun evaporation sources are reliable and simple to operate. They are equally suited for research or production applications. The compact design and ease of maintenance make it useful in practically all vacuum systems and for many varied applications. It has been used to evaporate refractory and dielectric materials, as well as the more common conductive and semiconductor materials. e-Gun evaporation sources are reliable and simple to operate. They are equally suited for research or production applications. |

|

Thermionics manufactures a full line of ion pumps. These are Standard / Noble / Hydrogen Diode Pumps and Triode Pumps. Each pump is reliable from one micron to 2 x 10e-11 Torr. All pumps are manufactured to exacting UHV standards. Pump bodies, flanges and element anodes are made of 304 stainless steel, bakeable to 450°C. Double re-entrant electrical insulators are made of high-quality aluminum oxide, bakeable to 450°C, and are equipped with sputter shields. Pump magnets are high-strength ferrites bakeable to 300°C. All pumps are manufactured to exacting UHV standards. Pump bodies, flanges and element anodes are made of 304 stainless steel, bakeable to 450°C. Double re-entrant electrical insulators are made of high-quality aluminum oxide, bakeable to 450°C, and are equipped with sputter shields. Pump magnets are high-strength ferrites bakeable to 300°C. |

|

|